What Mold Shapes Are Most Common for Branded Candle Lines?

What Mold Shapes Are Most Common for Branded Candle Lines?

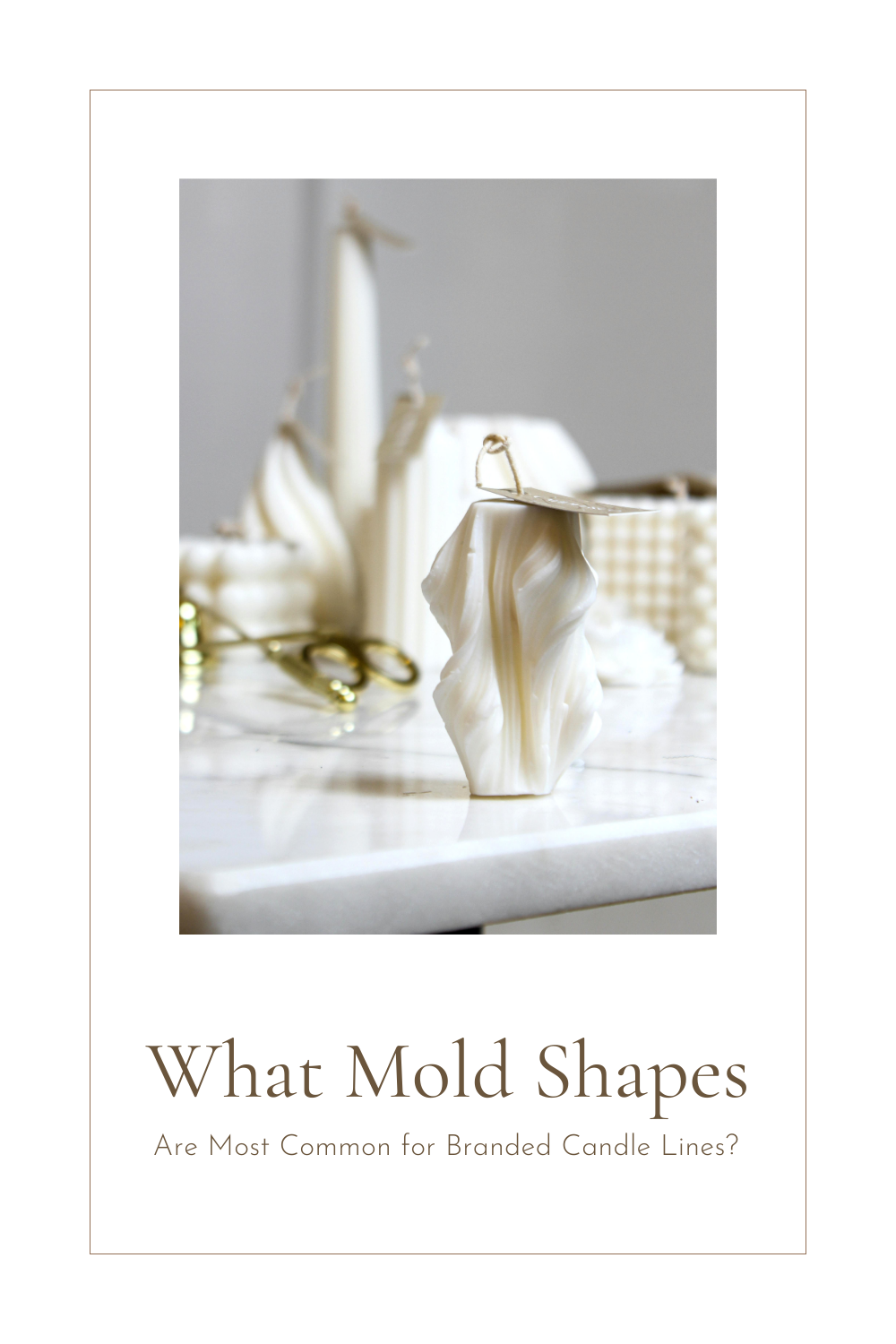

Branded candle lines need to balance visual appeal with production efficiency. The mold shapes a company selects often define its brand identity and help products stand out on store shelves.

These decisions affect everything from cost to customer recognition.

Most branded candle lines rely on classic pillars, tapered candles, and simple geometric shapes because these forms offer versatility, easy production, and broad market appeal.

However, some brands choose more distinctive options to create a unique presence. The right mold shape depends on the brand’s target audience and overall aesthetic goals.

This article explores the most popular mold shapes that successful candle brands use.

From traditional forms to creative designs, each shape offers different benefits for both makers and buyers.

Readers will learn about pillars, tapers, geometric options, novelty figures, and specialty beeswax forms that help candle companies build their market position.

Classic Pillar Molds

Classic pillar molds remain the foundation of most branded candle lines. These cylindrical molds create freestanding candles that burn evenly and look professional on store shelves.

Brands often choose durable custom candle molds for their pillar designs to maintain consistent quality across production runs.

The circular pillar stands as the most traditional shape in candle production. However, square and rectangular pillars have gained popularity in modern product lines.

These geometric forms offer a contemporary aesthetic that appeals to design-focused customers.

Polycarbonate and silicone materials dominate the pillar mold market. Polycarbonate molds deliver smooth surfaces and clean edges, which matter for premium branding.

Silicone molds provide flexibility and easy release, making them practical for high-volume production.

Most pillar molds come in standard heights between 3 and 9 inches. Brands typically stock multiple sizes to serve different customer needs and price points.

The diameter usually ranges from 2 to 4 inches for retail candles.

Tapered Candle Molds

Tapered candle molds create the classic, elegant candles that narrow from base to tip. These molds come in different materials, with metal and silicone being the most popular choices for branded candle lines.

Metal molds, particularly aluminum and tin-plate versions, offer excellent heat distribution and durability.

They produce smooth, professional results that appeal to brands that want a traditional look. However, metal molds require careful release techniques to avoid damage to the finished candles.

Silicone tapered molds have become more common in recent years. They allow for easy candle removal without special tools or techniques.

Many silicone options include reinforced outer shells that provide stability during the pour and cool-down process.

Most tapered molds range from 8 to 12 inches in height. The standard design features a pointed tip at the top and a wider base for stability.

Brands often choose tapered candles for dinner settings, ceremonies, and elegant home decor products because they convey sophistication and timeless style.

Geometric Silicone Molds

Geometric silicone molds have become a popular choice for branded candle lines. These molds produce candles with clean lines and modern shapes that appeal to contemporary customers.

The designs range from simple cubes and cylinders to more complex diamond patterns and abstract forms.

Silicone material offers several practical benefits for brands. The flexibility allows finished candles to release easily without damage to delicate edges.

These molds resist high temperatures and can be used repeatedly without losing their shape. Many brands choose geometric molds because they create consistent results across large production runs.

Common geometric shapes include hexagons, pyramids, spheres, and rectangular blocks. Some molds feature multiple cavities to produce several candles at once.

Abstract geometric designs also provide opportunities for brands to stand out with unique patterns.

The versatility of geometric molds suits different product lines. A brand can use the same basic shape in various sizes to create a cohesive collection.

These molds work well with different wax types and support creative color combinations that highlight the angular forms.

Novelty Figure Molds

Novelty figure molds allow candle makers to create unique shapes that stand out on retail shelves. These molds produce candles that look like animals, flowers, human figures, and other creative designs.

Brands often use them to connect with specific themes or seasonal events.

Silicone offers the best material choice for novelty molds because it bends easily. This flexibility helps remove complex shapes without damage to fine details.

The molds can capture intricate features like facial expressions, petals, or textured surfaces.

Latex molds also work well for detailed novelty candles. They reproduce precise features and allow for unusual asymmetric shapes that rigid molds cannot achieve.

However, latex requires more careful handling than silicone.

Brands that target gift markets or seasonal collections rely heavily on novelty figure molds. These shapes create emotional connections with buyers who look for candles as decorative pieces rather than just light sources.

The variety available lets companies develop signature shapes that become recognizable to their customers.

Beeswax Dome Molds

Dome molds create rounded, hemispherical candles that stand out on retail shelves. These molds produce smooth, curved surfaces that catch light in appealing ways.

The shape works well for brands that want a modern, minimal look.

Silicone dome molds are the most popular choice for beeswax candles. They allow for easy release of the finished product without damage to the curved surface.

The flexible material bends away from the wax, which prevents cracks or surface imperfections.

Dome candles typically range from small tealight sizes to larger statement pieces. The shape uses less material than traditional pillar candles of similar height.

However, the wider base provides stable support.

Many branded lines use dome molds to create signature collections. The shape looks professional and polished without complex details.

Beeswax fills these molds well because of its natural adhesive properties and smooth finish after cooling.

Which Mold Shapes Work for You?

Branded candle lines typically rely on a few proven shapes that appeal to customers and work well in production.

Cylinders, squares, and rectangles dominate the market because they look professional and can be made easily at scale.

However, luxury brands often add specialty shapes like spheres or geometric designs to stand out on shelves.

The right mold choice depends on brand identity, production capacity, and target customers.

Companies that understand these core shapes can create candle lines that sell well and represent their brand effectively.

Do you have any questions?

Sound off, below!

— Jennifer

PIN FOR LATER:

I am a girl from the UK with a lot of thoughts. I left the rat race of the corporate and marketing world to be my own boss. I write about life, finances, home design, fashion, and more. Hoping to inspire people every day. I’m a writer, a reader, and an old soul.